In order to optimise the internal material flow, the workshop of the Künzli sawmill in Krummenau was equipped with a new crane system. This was to enable the efficient transport of heavy loads both inside and on the forecourt. The spatial conditions posed a particular challenge. The low room height, due to the roof construction, left little room for manoeuvre for the installation of a crane system with sufficient lifting height. At the same time, the working area in the hall had to be designed to be as large as possible without compromising functionality when entering and exiting through the building opening. Precision was therefore required at every stage of the project - from planning and execution through to installation.

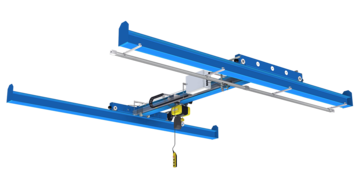

A suitable solution was found in collaboration with GIS AG. The manufacturer of electric chain hoists and crane systems installed a compact crane bridge on the existing 20 metre long crane runway, which makes optimum use of the limited space. The hoist, a GP1600 electric chain hoist with a load capacity of 2,500 kg, is arranged between the two crane girders to save space. The overall height was kept as low as possible in order to make optimum use of the available room height. For effortless handling, all travelling and lifting movements of the travelling crane are electric and can be conveniently operated by radio control.

The precise planning and realisation becomes particularly clear when the crane bridge moves out of the hall onto the forecourt. People often talk about a customised solution, but rarely has this expression been more appropriate. The minimal distance to the building opening shows how precisely the construction was adapted to the cramped conditions. Despite the challenging conditions, the result is a powerful and efficient crane solution that makes material transport at the Künzli sawmill much easier.