Konvekta AG from St. Gallen is the global technology leader in the field of high-performance energy recovery for ventilation and air conditioning systems. Its recirculating systems recover up to 95% of heat energy, resulting in significant energy savings and CO2 reductions.

With over 1,000 successfully implemented projects, Konvekta sets industry standards for applications in hospitals, laboratories and production buildings as well as universities, airports and sports stadiums.

The latest achievement is the Zero Emission Energy Recovery System (ZEERS). This allows fossil-free heating and cooling of fresh air in buildings and thus full air conditioning of the building air without fossil fuels. The proprietary software for the Konvekta controller ensures precise monitoring and control of the energy recovery system, guaranteeing maximum efficiency and reliability.

Long-standing collaboration between Konvekta and GIS

ZEERS has been realised as a showcase at the company's headquarters and can be viewed by visitors. The production and office building was remodelled and expanded in 2021 and 2022. Production capacity was more than doubled and the company is ideally equipped to meet the increasing demand resulting from the growing need for energy recovery and sustainability. During the planning and conversion phase, the long-standing collaboration with the electric chain hoist and crane manufacturer GIS was further intensified. In the production halls, where Konvekta manufactures the heat exchangers for the energy recovery systems, among other things, various GIS indoor cranes and lifting solutions ensure safe and efficient goods handling. Many of these have only been newly installed and commissioned in recent years.

Material transport from one workstation to the next

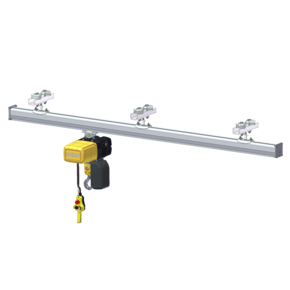

GISKB monorails play a decisive role in the production lines for heat exchanger elements by enabling smooth material transport between the individual work stations. The elements are first assembled in the stapling station, then suspended from the electric chain hoist and moved by hand along the crane rail to the soldering machine, washing station and inspection station. Several curves and three turntables ensure a customised and space-saving line layout. The latter are pneumatically operated and can be operated by radio control. The chain hoist travels into the turntable, changes direction by 90° if necessary and leaves it again on the outbound track.

For maximum flexibility and productivity, there are a total of 8 individual lifting units in the overhead conveyor, consisting of a GPM250 electric chain hoist with manual trolley. These all have a load capacity of 250 kg and are responsible for lifting and positioning the transported goods for the next work step. The chain hoists are powered via a conductor line that is integrated directly into the crane profile.

When planning the crane system, care was taken to keep its height as low as possible in order to maximise the lifting height. During soldering and inspection work on the underside of the vertically suspended heat exchanger elements, every centimetre of clearance to the ground is appreciated.

Transport of raw materials from outside the building

Another GIS crane system provides valuable services in Konvekta's bar storage facility. It has a span of 10.3 metres and a runway length of 22.1 metres. If required, the working range of the travelling crane can be extended by 5 m using a telescopic boom attached to the crane bridge. The raw material is transported from the area outside the building through an opening in the building to the production level on the first floor with the aid of the crane girder, which can be extended on one side. Permanent monitoring of the position of the telescopic boom by means of path measurement, built-in sensors and travelling limit switches guarantees maximum safety when operating the crane system. The jib can only be extended in defined areas and only if certain criteria are met. The automatic release for extending the crane girder from the building opening requires the door to be open and de-energised/not in operation. When the arm is extended, the crane only travels lengthways at crawling speed and stops automatically when it reaches critical areas, i.e. if there is a risk of the telescopic arm colliding with obstacles.

Two GIS GP500 electric chain hoists, each with a load capacity of 500 kg, are used as hoists for the overhead crane. To transport long and bulky goods, such as iron bars or machines during the renovation phase, the lifting movement of the two chain hoists is synchronised. To monitor this tandem operation, both hoist units are equipped with travel measurement via encoders. Interrupting the lifting or lowering process of one chain hoist automatically brings the other to a standstill.

All movements are performed by frequency-controlled electric drives with soft start for careful transport and precise positioning of the load. The overhead travelling crane is controlled via a radio remote control.

More exciting projects in the future

The reliability and longevity of GIS electric chain hoists and crane systems is not evident in the brochure, but in daily use. The situation is similar with Konvekta's ERG systems, where the savings in energy costs and CO2 emissions only become clearly visible to customers after a certain period of operation. In terms of environmental protection and sustainability, Konvekta plays an important role with its energy recovery systems. Efficiency is one of the keys to success and extends from the transport of the delivered raw material through the entire manufacturing process to the functioning of the end product.

As standing still means going backwards, Konvekta and GIS are already planning the installation of additional crane systems to further improve operational safety and facilitate the handling of goods. The successful collaboration between the two companies will therefore continue in the future.

Technical data / fact sheet

GISKB monorail with curves and turntables

- The GISKB monorail system consists of GISKBII steel profiles. In addition to straight profiles, the crane system also includes curves and 3 turntables for customised line routing to connect the work stations.

- The turnstiles are pneumatically driven and can be operated by radio control. The turnstiles can be controlled individually using a hand-held transmitter.

- There are a total of 8 electric chain hoists of type GPM250/1NF in the crane system. Each has a load capacity of 250 kg and a lifting height of 4.4 metres. The lifting speed is 8/2 m/min. Each chain hoist has a 2-button control switch with emergency stop for control purposes. All chain hoists are equipped with a manual trolley for moving along the crane rail.

- Power is supplied to the chain hoists via a conductor line integrated into the crane profile.

- The crane system is mounted on rigid suspensions to the concrete ceiling.

Double-girder overhead travelling crane with telescopic jib

- The crane system is a double-girder underslung travelling crane with a double telescopic jib. The crane girder length is 10.3 metres (span 9.7 metres) and the crane runway length is 22.1 metres.

- The crane girder has a telescopic boom. This jib is 10.3 m long and can be extended on one side. This increases the crane's working range by around 5 metres.

- The position of the telescopic boom is monitored by sensors, path measurement and travelling limit switches. This ensures that the extension can only take place in the 3 defined areas. When the boom is extended, travelling lengthways is only possible in slow speed. To prevent collisions when the boom is extended, the longitudinal movement is automatically stopped when the defined areas are left.

- The telescopic arm can only be extended in the area of the door if a double automatic release is present. The door must be open and de-energised / out of operation.

- Two electric chain hoists of type GPO500/1NL FU are used as hoists. These are raised between the two crane girder profiles by means of an intermediate structure and have a load capacity of 500 kg each. A mechanical spacer prevents the two lifting units from moving together.

- Chain hoists are used in tandem operation to lift long goods, such as iron bars, so that the lifting movement takes place in parallel. For monitoring purposes, the chain hoists are equipped with a travel measurement system using an encoder. An interruption in the lifting or lowering process of one chain hoist automatically causes the other to stop.

- A lifting height of 8 metres is available for transporting goods from the forecourt of the building to the first floor with the crane.

- The trolley and crane travel is performed by GMFO motorised trolleys in conjunction with a frequency inverter. The two travelling speeds can be continuously programmed in the range of 3.6 - 20 m/min.

- The travelling crane has a central crane control system. It is operated by radio control with the following functions: Up/down (chain hoist 1 + 2), left/right, forwards/backwards, telescopic boom extension/retraction, horn, emergency stop.

- The electrical supply is 3x400V, 50Hz, via a conductor line in the longitudinal direction and via an energy chain in the cross direction.